Post-Op Follow-Up Schedule That Prevents Prosthetic Delays (For Clinicians)

For many clinicians, the surgery is only the first step. What happens after the operation

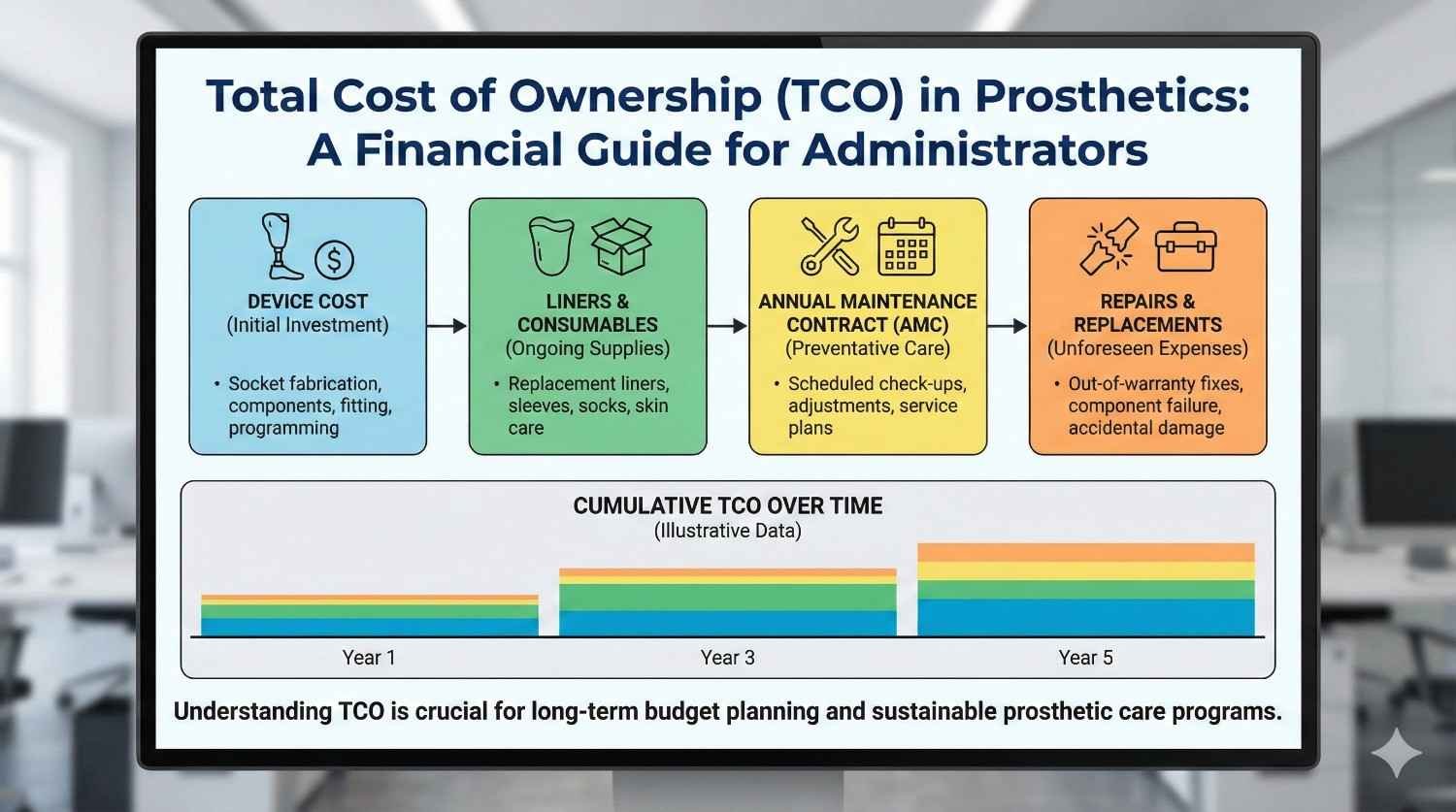

When hospitals and prosthetic programs look at costs, they often see only the device price. That number feels clear, fixed, and easy to compare. But in real life, prosthetics do not behave like one-time purchases. They behave like long-term systems with ongoing expenses, hidden drains, and decisions that quietly shape budgets year after year.

This article is written for hospital administrators, procurement heads, and program managers who want control, not surprises. We will break down the total cost of ownership in prosthetics in very simple terms. This includes the device, liners, annual maintenance contracts, repairs, downtime, and indirect costs that rarely appear in spreadsheets. The goal is to help you budget better, negotiate smarter, and build prosthetic programs that stay financially stable over time.

Most prosthetic budgets begin and end with the device invoice.

This creates a false sense of control because many important costs arrive later and in smaller pieces.

Over time, these smaller expenses add up and often exceed the original device cost.

Total cost of ownership brings these hidden layers into view.

A prosthetic device is used every day for years, not weeks.

It interacts with the human body, the environment, and the hospital system continuously.

Wear, tear, adjustments, and replacements are natural outcomes of this use.

TCO helps admins plan for this reality instead of reacting to it.

The first year often feels manageable because the focus is on fitting and discharge.

Problems usually surface in the second and third years through liner replacements, repairs, and service needs.

These costs often sit outside the original budget approval.

TCO planning prevents this cycle of surprise and justification.

The device is only the starting point in the ownership journey.

Every prosthesis relies on consumables, services, and follow-up care to stay usable.

Ignoring these elements creates incomplete cost projections.

TCO captures the full picture from day one.

Costs in prosthetics are spread across time.

What looks affordable in year one may become expensive by year five.

TCO forces admins to ask how costs behave over the full life of the device.

This time-based view improves long-term planning.

A prosthesis may be owned by the hospital or patient, but its use defines cost.

High-use devices need more maintenance and consumables.

Low-use devices risk abandonment, which is also a cost failure.

TCO considers both extremes.

The prosthetic device forms the base of total cost.

This includes sockets, joints, feet or hands, and control systems.

Prices vary widely based on technology level and customization.

However, this base layer rarely reflects final spend.

Liners are consumables that sit between the limb and the socket.

They wear out due to sweat, friction, and daily use.

Most users need multiple liner replacements each year.

These recurring costs are often underestimated in budgets.

Suspension systems such as sleeves, belts, or locks also wear over time.

Poor suspension increases discomfort and repair needs.

Regular replacement is part of healthy prosthetic use.

TCO models must include these cycles.

Liners absorb sweat and body oils every day.

They stretch, thin out, and lose grip over time.

As liners degrade, fit quality drops and skin issues increase.

Replacement becomes unavoidable for safe use.

Most active users need liner replacement every three to six months.

Less active users may extend this slightly, but not indefinitely.

Delaying replacement often leads to higher medical and repair costs later.

Predictable planning is cheaper than reactive spending.

Basic liners cost less but may wear faster.

Advanced liners cost more but often last longer and reduce skin issues.

Choosing purely on price can increase long-term spend.

Admins should compare cost per month, not per unit.

Annual maintenance contracts usually cover routine servicing and minor repairs.

They may include inspections, adjustments, and basic part replacements.

AMCs provide cost predictability and reduce emergency spending.

However, coverage details vary widely.

Many AMCs exclude consumables like liners and sleeves.

Major component failures may also be excluded or capped.

Admins should read AMC terms carefully before assuming full coverage.

Misunderstood AMCs lead to budget overruns.

AMCs are most useful for advanced or high-use prosthetic devices.

They smooth out costs and reduce downtime.

For low-use devices, ad hoc repairs may be cheaper.

Matching AMC choice to usage pattern improves TCO.

Prosthetic devices operate in tough conditions.

Dust, moisture, impact, and daily stress cause wear.

Even well-made devices need occasional repair.

Ignoring this reality leads to poor budgeting.

These include parts, labor, and service charges.

Costs vary based on device complexity and availability of spares.

Imported components often cost more and take longer to source.

Downtime adds hidden cost.

When a device is under repair, the user may need extra care.

Hospital visits increase and rehab progress may stall.

Staff time and patient dissatisfaction also rise.

These indirect costs matter in TCO thinking.

Downtime is the period when the prosthesis is not usable.

This can be due to repair delays, part shortages, or service gaps.

During downtime, functional independence drops sharply.

This has both human and financial impact.

Patients may return to the hospital for support.

Rehab schedules get disrupted and staff time increases.

Emergency fittings or temporary solutions add cost.

Downtime is rarely free.

Local service support reduces repair delays.

Spare availability and clear service agreements matter.

Admins who plan for uptime reduce long-term cost.

Service quality directly affects TCO.

Imported devices often rely on international supply chains.

Delays due to shipping or customs increase downtime.

Local devices usually have faster spare access.

Time savings translate into cost savings.

Local service teams are easier to reach and schedule.

This reduces travel and coordination costs.

Faster resolution prevents small issues from becoming major repairs.

Service proximity is a TCO advantage.

Imported prices may fluctuate with currency changes.

Local pricing is often more stable.

This predictability helps long-term budgeting.

Admins should factor this into ownership decisions.

Active users stress components more heavily.

They need more frequent liner changes and adjustments.

Their TCO is higher but so is functional benefit.

Planning prevents cost shocks.

These users may need fewer replacements.

However, poor fit tolerance can increase medical visits.

Comfort-focused choices often reduce indirect costs.

TCO is not always lower just because activity is low.

Children outgrow sockets quickly.

Frequent refits and replacements are unavoidable.

TCO planning is essential in pediatric programs.

Short-term savings rarely work here.

TCO allows fair comparison across suppliers.

A cheaper device with high service cost may be more expensive overall.

Admins should ask vendors for multi-year cost estimates.

This shifts negotiations to value, not discounts.

Including liners, AMC, and repairs upfront reduces mid-year budget stress.

Finance teams appreciate predictable spend.

Programs run more smoothly with fewer approvals.

TCO supports operational calm.

Clear TCO logic helps justify spending decisions.

Auditors prefer long-term thinking over reactive fixes.

Documentation improves trust and approval speed.

Transparency protects admins.

Most prosthetic budgets are planned on a one-year cycle because that is how hospital finances operate.

Prosthetic ownership, however, rarely fits neatly into a single year.

Devices continue to generate costs long after the initial fitting, often in small but frequent amounts.

Looking only at year one hides the true financial behavior of the program.

In the first year, the largest expense is the device and initial fitting.

In the second year, liner replacements, minor repairs, and service visits become more visible.

By the third year, component wear, suspension changes, and occasional major repairs appear.

A three-year view already tells a very different cost story than a one-year view.

Many prosthetic components are designed to last four to five years with proper care.

This makes five years a practical horizon for ownership planning.

Over this period, consumables and service costs often equal or exceed the device cost.

Admins who plan five years ahead avoid repeated approval cycles and budget shocks.

The hospital incurs the device cost, fitting charges, and initial rehab coordination.

Liner usage is high as patients adapt, leading to early replacements.

Service needs are mostly adjustments rather than repairs.

Costs feel front-loaded but still predictable.

By the second year, daily use becomes consistent.

Liner replacement becomes the most frequent expense.

Small repairs, alignment checks, and suspension changes appear.

These costs are often spread out and easy to miss without tracking.

Component wear becomes more evident over time.

Some users need major part replacements or socket refits.

At this stage, admins often face decisions about upgrades or continued repair.

Good TCO planning makes these decisions calm rather than urgent.

Upper-limb prosthetics often have lower liner costs but higher component sensitivity.

Myoelectric systems include batteries, electronics, and control units.

Body-powered systems have lower electronics cost but higher harness wear.

Each category creates a different ownership curve.

Rechargeable batteries degrade over time.

Most need replacement every one to two years.

These costs are often forgotten during procurement discussions.

Including them early improves forecast accuracy.

Cables, gloves, and cosmetic covers wear with use.

These parts are replaced more often than major components.

Individually they seem minor, but together they add up.

TCO captures these cumulative effects.

Vendors are used to negotiating on unit price.

Admins who introduce TCO change the dynamic.

Instead of asking for discounts, they ask for cost stability over time.

This often leads to more meaningful concessions.

Admins should ask how often liners typically need replacement.

They should ask which parts fail most often and what repairs cost.

They should also ask about service response time and spare availability.

These questions reveal real ownership cost.

Two devices may look similar in price and function.

However, one may have higher liner costs or slower service.

A simple TCO comparison over three years often reveals the better choice.

Admins should document this comparison for internal approvals.

Lowest price procurement often leads to higher long-term spend.

Hospitals can revise policies to include ownership cost as a criterion.

This encourages vendors to compete on service and durability.

Quality improves when policies reward value.

Using too many liner or accessory types increases complexity.

Standardization simplifies inventory and reduces waste.

Bulk purchasing also improves pricing.

Admins can use TCO logic to justify standardization.

Clinical preferences affect TCO outcomes.

Procurement teams should involve clinicians in TCO discussions.

When both sides understand trade-offs, decisions improve.

Alignment reduces conflict and rework.

Liners and sleeves follow predictable replacement cycles.

Hospitals can forecast demand based on active patient numbers.

This reduces emergency purchases and stock-outs.

Predictability lowers cost and stress.

Overstocking consumables ties up capital.

Some materials degrade or expire if unused.

TCO planning helps balance availability with efficiency.

Right-sized inventory supports cash flow.

When service visits are planned, consumable needs can be aligned.

This coordination reduces repeat visits and shipping costs.

Operational efficiency improves.

Admins benefit from integrated planning.

Not all AMCs are good or bad by default.

Their value depends on device complexity and usage.

Admins should compare AMC cost against expected repair spend.

This comparison clarifies whether an AMC makes sense.

Many AMCs exclude key items by default.

Admins can negotiate inclusion of common repairs or priority service.

Clear scope reduces dispute and surprise.

Well-designed AMCs improve uptime.

AMCs should not be set and forgotten.

Admins should review usage, response times, and outcomes yearly.

Poorly performing contracts should be renegotiated or discontinued.

Active management protects TCO.

Every day of downtime increases indirect costs.

Patients return for help, rehab slows, and dissatisfaction rises.

Faster repair resolution reduces these knock-on effects.

Admins should value speed, not just price.

Service response time should be written into agreements.

Clear timelines reduce ambiguity.

Local support should be prioritized where possible.

Service access is a financial lever.

Some programs maintain backup components or temporary solutions.

This reduces disruption during repairs.

While it adds small upfront cost, it saves larger indirect costs.

TCO thinking supports these decisions.

Finance teams prefer structured, forward-looking explanations.

TCO data shows that spending is planned, not accidental.

This improves audit outcomes.

Admins gain credibility.

Leadership often sees rising costs without context.

TCO allows admins to explain why costs rise and where they stabilize.

Context reduces alarm and builds trust.

Transparency strengthens support.

As TCO data accumulates, forecasts improve.

Variance reduces over time.

Budgets become more reliable.

This stability benefits the entire hospital.

The most important shift an administrator can make is moving from a buyer mindset to an owner mindset.

Buying focuses on price and approval, while ownership focuses on performance, upkeep, and long-term stability.

When prosthetics are treated as owned systems rather than purchased items, cost control improves naturally.

This shift alone prevents many avoidable budget issues.

TCO should not live only in annual budget meetings.

It should inform vendor selection, service contracts, inventory planning, and even clinical discussions.

When admins ask how a decision affects ownership cost over time, better choices follow.

Consistency in this lens builds financial discipline across teams.

Before approving any prosthetic purchase, clarify how long the device is expected to remain in use.

This includes realistic usage based on patient profile, not brochure claims.

Life expectancy sets the timeline for all other cost planning.

Without this step, TCO estimates remain vague.

Identify liners, sleeves, gloves, batteries, cables, and cosmetic covers linked to the device.

Estimate how often each item needs replacement under normal use.

Multiply this by expected years of use to reveal the real consumable cost.

This exercise alone often surprises finance teams.

Review typical repair patterns for the device category.

Include routine adjustments, common failures, and major part replacements.

Use real-world data where possible instead of theoretical durability.

Service patterns shape both cost and downtime.

Compare AMC cost against expected repair and service spend.

Include response time, spare availability, and coverage limits.

Choose the option that provides better predictability, not just lower headline cost.

Re-evaluate this choice annually.

Estimate what happens when a device is unavailable.

Include extra visits, rehab delays, and staff time.

Even rough estimates improve decision quality.

Downtime is often the hidden cost driver.

When comparing two prosthetic options, place them side by side across five years.

Include device cost, consumables, AMC or repairs, and expected downtime.

Avoid mixing one-time and recurring costs in the same column.

Clarity matters more than precision.

Devices that look cheaper upfront often show higher long-term cost.

Conversely, higher-priced devices sometimes stabilize spending over time.

Seeing the full picture reduces emotional decision-making.

Admins gain confidence in approvals.

Hospitals should formally include ownership cost in procurement criteria.

This can be done without complex scoring systems.

Even a basic three-year TCO estimate improves outcomes.

Policy change reinforces good habits.

Vendors respond to what hospitals ask for.

When admins ask about liners, service frequency, and downtime, transparency improves.

This pushes the market toward better long-term solutions.

Informed buyers shape better offerings.

Too much variation increases inventory, training, and service costs.

Standardization around a few proven systems reduces ownership complexity.

TCO logic provides a strong justification for this move.

Consistency saves money quietly.

Clinicians focus on outcomes and patient comfort.

Admins focus on budgets and sustainability.

TCO bridges this gap by showing how comfort, fit, and service affect cost.

Shared understanding reduces friction.

Finance teams value predictability and documentation.

TCO provides both.

It explains why costs exist and how they are planned.

This improves audit confidence and reduces scrutiny stress.

As people change roles, TCO knowledge can be lost.

Hospitals should document their ownership assumptions and update them regularly.

This continuity protects long-term planning.

Institutional memory matters.

Ownership cost changes as usage patterns change.

Static models become outdated quickly.

Regular review keeps TCO relevant.

Living models outperform fixed ones.

Planning for every extreme can paralyze decisions.

Use realistic averages with sensible buffers.

Balance caution with practicality.

Good planning is calm, not fearful.

Discomfort, skin issues, and frustration increase service use.

Better patient experience often lowers ownership cost.

Admins should listen to clinical feedback closely.

Human outcomes affect financial outcomes.

Total cost of ownership is not about spending less at any cost.

It is about spending wisely, predictably, and with foresight.

Prosthetic programs succeed when costs are understood, planned, and aligned with real use.

TCO brings structure to what often feels unpredictable.

At RoboBionics, we work closely with hospitals across India and see how TCO thinking changes outcomes.

Programs that plan ownership carefully face fewer crises, make better vendor choices, and deliver more stable care to patients.

The most resilient prosthetic programs are not the cheapest ones, but the ones with the clearest understanding of what ownership truly means.

For many clinicians, the surgery is only the first step. What happens after the operation

For trauma amputees, the journey does not begin at the prosthetic clinic. It begins much

Amputation after cancer is not just a surgical event. It is the end of one

When a child loses a limb, the challenge is never only physical. A child’s body

Last updated: November 10, 2022

Thank you for shopping at Robo Bionics.

If, for any reason, You are not completely satisfied with a purchase We invite You to review our policy on refunds and returns.

The following terms are applicable for any products that You purchased with Us.

The words of which the initial letter is capitalized have meanings defined under the following conditions. The following definitions shall have the same meaning regardless of whether they appear in singular or in plural.

For the purposes of this Return and Refund Policy:

Company (referred to as either “the Company”, “Robo Bionics”, “We”, “Us” or “Our” in this Agreement) refers to Bionic Hope Private Limited, Pearl Haven, 1st Floor Kumbharwada, Manickpur Near St. Michael’s Church Vasai Road West, Palghar Maharashtra 401202.

Goods refer to the items offered for sale on the Website.

Orders mean a request by You to purchase Goods from Us.

Service refers to the Services Provided like Online Demo and Live Demo.

Website refers to Robo Bionics, accessible from https://robobionics.in

You means the individual accessing or using the Service, or the company, or other legal entity on behalf of which such individual is accessing or using the Service, as applicable.

You are entitled to cancel Your Service Bookings within 7 days without giving any reason for doing so, before completion of Delivery.

The deadline for cancelling a Service Booking is 7 days from the date on which You received the Confirmation of Service.

In order to exercise Your right of cancellation, You must inform Us of your decision by means of a clear statement. You can inform us of your decision by:

We will reimburse You no later than 7 days from the day on which We receive your request for cancellation, if above criteria is met. We will use the same means of payment as You used for the Service Booking, and You will not incur any fees for such reimbursement.

Please note in case you miss a Service Booking or Re-schedule the same we shall only entertain the request once.

In order for the Goods to be eligible for a return, please make sure that:

The following Goods cannot be returned:

We reserve the right to refuse returns of any merchandise that does not meet the above return conditions in our sole discretion.

Only regular priced Goods may be refunded by 50%. Unfortunately, Goods on sale cannot be refunded. This exclusion may not apply to You if it is not permitted by applicable law.

You are responsible for the cost and risk of returning the Goods to Us. You should send the Goods at the following:

We cannot be held responsible for Goods damaged or lost in return shipment. Therefore, We recommend an insured and trackable courier service. We are unable to issue a refund without actual receipt of the Goods or proof of received return delivery.

If you have any questions about our Returns and Refunds Policy, please contact us:

Last Updated on: 1st Jan 2021

These Terms and Conditions (“Terms”) govern Your access to and use of the website, platforms, applications, products and services (ively, the “Services”) offered by Robo Bionics® (a registered trademark of Bionic Hope Private Limited, also used as a trade name), a company incorporated under the Companies Act, 2013, having its Corporate office at Pearl Heaven Bungalow, 1st Floor, Manickpur, Kumbharwada, Vasai Road (West), Palghar – 401202, Maharashtra, India (“Company”, “We”, “Us” or “Our”). By accessing or using the Services, You (each a “User”) agree to be bound by these Terms and all applicable laws and regulations. If You do not agree with any part of these Terms, You must immediately discontinue use of the Services.

1.1 “Individual Consumer” means a natural person aged eighteen (18) years or above who registers to use Our products or Services following evaluation and prescription by a Rehabilitation Council of India (“RCI”)–registered Prosthetist.

1.2 “Entity Consumer” means a corporate organisation, nonprofit entity, CSR sponsor or other registered organisation that sponsors one or more Individual Consumers to use Our products or Services.

1.3 “Clinic” means an RCI-registered Prosthetics and Orthotics centre or Prosthetist that purchases products and Services from Us for fitment to Individual Consumers.

1.4 “Platform” means RehabConnect™, Our online marketplace by which Individual or Entity Consumers connect with Clinics in their chosen locations.

1.5 “Products” means Grippy® Bionic Hand, Grippy® Mech, BrawnBand™, WeightBand™, consumables, accessories and related hardware.

1.6 “Apps” means Our clinician-facing and end-user software applications supporting Product use and data collection.

1.7 “Impact Dashboard™” means the analytics interface provided to CSR, NGO, corporate and hospital sponsors.

1.8 “Services” includes all Products, Apps, the Platform and the Impact Dashboard.

2.1 Individual Consumers must be at least eighteen (18) years old and undergo evaluation and prescription by an RCI-registered Prosthetist prior to purchase or use of any Products or Services.

2.2 Entity Consumers must be duly registered under the laws of India and may sponsor one or more Individual Consumers.

2.3 Clinics must maintain valid RCI registration and comply with all applicable clinical and professional standards.

3.1 Robo Bionics acts solely as an intermediary connecting Users with Clinics via the Platform. We do not endorse or guarantee the quality, legality or outcomes of services rendered by any Clinic. Each Clinic is solely responsible for its professional services and compliance with applicable laws and regulations.

4.1 All content, trademarks, logos, designs and software on Our website, Apps and Platform are the exclusive property of Bionic Hope Private Limited or its licensors.

4.2 Subject to these Terms, We grant You a limited, non-exclusive, non-transferable, revocable license to use the Services for personal, non-commercial purposes.

4.3 You may not reproduce, modify, distribute, decompile, reverse engineer or create derivative works of any portion of the Services without Our prior written consent.

5.1 Limited Warranty. We warrant that Products will be free from workmanship defects under normal use as follows:

(a) Grippy™ Bionic Hand, BrawnBand® and WeightBand®: one (1) year from date of purchase, covering manufacturing defects only.

(b) Chargers and batteries: six (6) months from date of purchase.

(c) Grippy Mech™: three (3) months from date of purchase.

(d) Consumables (e.g., gloves, carry bags): no warranty.

5.2 Custom Sockets. Sockets fabricated by Clinics are covered only by the Clinic’s optional warranty and subject to physiological changes (e.g., stump volume, muscle sensitivity).

5.3 Exclusions. Warranty does not apply to damage caused by misuse, user negligence, unauthorised repairs, Acts of God, or failure to follow the Instruction Manual.

5.4 Claims. To claim warranty, You must register the Product online, provide proof of purchase, and follow the procedures set out in the Warranty Card.

5.5 Disclaimer. To the maximum extent permitted by law, all other warranties, express or implied, including merchantability and fitness for a particular purpose, are disclaimed.

6.1 We collect personal contact details, physiological evaluation data, body measurements, sensor calibration values, device usage statistics and warranty information (“User Data”).

6.2 User Data is stored on secure servers of our third-party service providers and transmitted via encrypted APIs.

6.3 By using the Services, You consent to collection, storage, processing and transfer of User Data within Our internal ecosystem and to third-party service providers for analytics, R&D and support.

6.4 We implement reasonable security measures and comply with the Information Technology Act, 2000, and Information Technology (Reasonable Security Practices and Procedures and Sensitive Personal Data or Information) Rules, 2011.

6.5 A separate Privacy Policy sets out detailed information on data processing, user rights, grievance redressal and cross-border transfers, which forms part of these Terms.

7.1 Pursuant to the Information Technology Rules, 2021, We have given the Charge of Grievance Officer to our QC Head:

- Address: Grievance Officer

- Email: support@robobionics.in

- Phone: +91-8668372127

7.2 All support tickets and grievances must be submitted exclusively via the Robo Bionics Customer Support portal at https://robobionics.freshdesk.com/.

7.3 We will acknowledge receipt of your ticket within twenty-four (24) working hours and endeavour to resolve or provide a substantive response within seventy-two (72) working hours, excluding weekends and public holidays.

8.1 Pricing. Product and Service pricing is as per quotations or purchase orders agreed in writing.

8.2 Payment. We offer (a) 100% advance payment with possible incentives or (b) stage-wise payment plans without incentives.

8.3 Refunds. No refunds, except pro-rata adjustment where an Individual Consumer is medically unfit to proceed or elects to withdraw mid-stage, in which case unused stage fees apply.

9.1 Users must follow instructions provided by RCI-registered professionals and the User Manual.

9.2 Users and Entity Consumers shall indemnify and hold Us harmless from all liabilities, claims, damages and expenses arising from misuse of the Products, failure to follow professional guidance, or violation of these Terms.

10.1 To the extent permitted by law, Our total liability for any claim arising out of or in connection with these Terms or the Services shall not exceed the aggregate amount paid by You to Us in the twelve (12) months preceding the claim.

10.2 We shall not be liable for any indirect, incidental, consequential or punitive damages, including loss of profit, data or goodwill.

11.1 Our Products are classified as “Rehabilitation Aids,” not medical devices for diagnostic purposes.

11.2 Manufactured under ISO 13485:2016 quality management and tested for electrical safety under IEC 60601-1 and IEC 60601-1-2.

11.3 Products shall only be used under prescription and supervision of RCI-registered Prosthetists, Physiotherapists or Occupational Therapists.

We do not host third-party content or hardware. Any third-party services integrated with Our Apps are subject to their own terms and privacy policies.

13.1 All intellectual property rights in the Services and User Data remain with Us or our licensors.

13.2 Users grant Us a perpetual, irrevocable, royalty-free licence to use anonymised usage data for analytics, product improvement and marketing.

14.1 We may amend these Terms at any time. Material changes shall be notified to registered Users at least thirty (30) days prior to the effective date, via email and website notice.

14.2 Continued use of the Services after the effective date constitutes acceptance of the revised Terms.

Neither party shall be liable for delay or failure to perform any obligation under these Terms due to causes beyond its reasonable control, including Acts of God, pandemics, strikes, war, terrorism or government regulations.

16.1 All disputes shall be referred to and finally resolved by arbitration under the Arbitration and Conciliation Act, 1996.

16.2 A sole arbitrator shall be appointed by Bionic Hope Private Limited or, failing agreement within thirty (30) days, by the Mumbai Centre for International Arbitration.

16.3 Seat of arbitration: Mumbai, India.

16.4 Governing law: Laws of India.

16.5 Courts at Mumbai have exclusive jurisdiction over any proceedings to enforce an arbitral award.

17.1 Severability. If any provision is held invalid or unenforceable, the remainder shall remain in full force.

17.2 Waiver. No waiver of any breach shall constitute a waiver of any subsequent breach of the same or any other provision.

17.3 Assignment. You may not assign your rights or obligations without Our prior written consent.

By accessing or using the Products and/or Services of Bionic Hope Private Limited, You acknowledge that You have read, understood and agree to be bound by these Terms and Conditions.